Pulasitiki nkhungu ndi chida chomwe chimagwirizana ndi makina opangira pulasitiki mumakampani opanga pulasitiki kuti apatse zinthu zapulasitiki kasinthidwe ndi kukula kwake. Malingana ndi njira zosiyanasiyana zopangira, zikhoza kugawidwa mumitundu yosiyanasiyana ya nkhungu.

1. High-expansion polystyrene akamaumba kufa

Ndi mtundu wa nkhungu yomwe imagwiritsa ntchito polystyrene (zopangidwa ndi mikanda yopangidwa ndi polystyrene ndi thovu) zopangira kupanga zida zopangira thovu zamitundu yosiyanasiyana yomwe mukufuna.

Mfundo yake ndi yakuti polystyrene yowonjezereka imatha kutenthedwa mu nkhungu, kuphatikizapo mitundu iwiri ya zojambulajambula zosavuta zamanja ndi ma hydraulic molunjika-kupyolera mu nkhungu zapulasitiki za thovu, zomwe zimagwiritsidwa ntchito makamaka popanga zinthu zopangira katundu wa mafakitale. Zida zopangira nkhungu zoterezi ndi aluminiyamu, chitsulo chosapanga dzimbiri, mkuwa, ndi zina.

2. Compression nkhungu

Kuphatikiza psinjika akamaumba ndi jekeseni akamaumba awiri structural nkhungu. Ndiwo mtundu wa nkhungu womwe umagwiritsidwa ntchito kuumba mapulasitiki a thermosetting, ndipo zida zawo zofananira ndi makina osindikizira.

Njira yopopera yopopera Molingana ndi mawonekedwe a pulasitiki, nkhungu imatenthedwa ndi kutentha komwe kumawumbidwa (nthawi zambiri 103 ° 108 °), ndiye kuti ufa wopopera umayikidwa mumtsempha wa nkhungu ndi chipinda chodyera, nkhungu imatsekedwa, ndipo pulasitiki imatenthedwa ndi kutentha kwakukulu komanso kuthamanga kwambiri. Kufewetsa kutuluka kwa viscous, kulimbitsa ndi kupanga pakapita nthawi, ndikukhala mawonekedwe omwe amafunidwa.

Kusiyana pakati pa jekeseni ndi kuponderezana ndikumangirira ndikuti palibe chipinda chodyeramo chosiyana. Chikombolecho chimatsekedwa chisanapangidwe, ndipo pulasitiki imatenthedwa m'chipinda chodyera ndipo imakhala yotulutsa viscous. Pansi pa kukakamizidwa, imasinthidwa ndikufinyidwa mu nkhungu kuti ikhale yolimba ndi kupanga.

The psinjika nkhungu makamaka wapangidwa patsekeke, kudyetsa patsekeke, kutsogolera limagwirira, ejecting mbali, Kutentha dongosolo, etc. jekeseni zisamere nkhungu chimagwiritsidwa ntchito ma CD zigawo magetsi. Zida zomwe zimagwiritsidwa ntchito popanga nkhungu zopopera zimakhala zofanana ndi jekeseni.

3. Jekeseni nkhungu

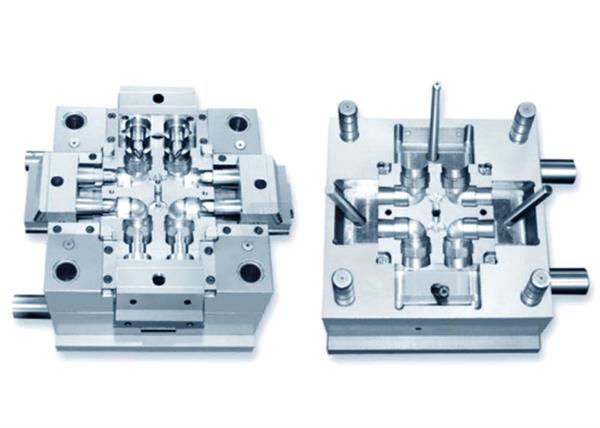

Makamaka nkhungu yomwe imagwiritsidwa ntchito kwambiri popanga zigawo za thermoplastic. Zida zopangira zofananira ndi nkhungu ya jakisoni ndi makina opangira jakisoni. Pulasitiki imatenthedwa poyamba ndikusungunuka mu mbiya yotentha pansi pa makina opangira jekeseni. Pansi pa kukankhira pulagi, amalowa mu nkhungu patsekeke kudzera mu jekeseni akamaumba makina nozzle ndi kutsanulira dongosolo nkhungu, ndi pulasitiki utakhazikika ndi kuumitsa kupanga, ndipo mankhwala analandira ndi kugwetsa.

Kapangidwe kake kamakhala kopangidwa ndi zigawo, kutsanulira, kutsanulira, kuwongolera, makina okankhira kunja, dongosolo lowongolera kutentha, dongosolo lotulutsa mpweya, magawo othandizira ndi magawo ena, ndipo amapangidwa ndi chitsulo chapulasitiki. Njira yopangira jakisoni nthawi zambiri imakhala yoyenera kupanga zinthu za thermoplastic. The mankhwala pulasitiki opangidwa ndi jekeseni akamaumba ndondomeko ndi lalikulu kwambiri. Kuyambira zofunikira zatsiku ndi tsiku kupita ku zida zosiyanasiyana zamagetsi ndi zida zamagalimoto, zonse zimapangidwa ndi nkhungu za jakisoni. Imodzi mwa njira zomwe zimagwiritsidwa ntchito kwambiri popanga zinthu zapulasitiki.

4. Kuwomba nkhungu

Chikombole chomwe chimagwiritsidwa ntchito popanga zinthu zapulasitiki zopanda kanthu (monga mabotolo a zakumwa, mankhwala a tsiku ndi tsiku ndi zotengera zina). Mawonekedwe a nkhonya akamaumba makamaka zikuphatikizapo extrusion kuwomba akamaumba ndi jekeseni akamaumba malinga ndi ndondomeko mfundo. Mfundoyi makamaka imaphatikizapo kuwombera kwa extrusion, kuwombera jekeseni, kuumba jekeseni yowonjezera (yomwe imadziwika kuti jekeseni kutambasula), kupopera kwamitundu yambiri, kupukuta mapepala, ndi zina zotero. kuwomba akamaumba makina, ndi kuwomba akamaumba ndi oyenera kupanga mankhwala thermoplastic. Mapangidwe a nkhungu yowombayo ndi osavuta, ndipo zida zomwe zimagwiritsidwa ntchito nthawi zambiri zimapangidwa ndi kaboni.

5. Extrusion kufa

A mtundu nkhungu ntchito kupanga mosalekeza zoboola pakati mankhwala pulasitiki, amatchedwanso extrusion akamaumba mutu, chimagwiritsidwa ntchito pokonza mipope, mipiringidzo, monofilaments, mbale, mafilimu, waya ndi chingwe cladding, profiled zipangizo, etc.

The lolingana kupanga zida ndi pulasitiki extruder. Mfundo yake ndi yakuti pulasitiki yolimba imasungunuka ndi kupangidwa ndi pulasitiki pansi pa kutentha ndi kuzungulira kwa wononga kwa extruder, ndipo imapangidwa mofanana ndi mawonekedwe a kufa kudzera mukufa kwa mawonekedwe enieni. Zopitilira pulasitiki. Zopangira zake makamaka zimakhala zitsulo zopangidwa ndi kaboni, zida za aloyi, ndi zina zambiri, ndipo ma extrusion dies amapangidwanso ndi zinthu zosamva kuvala monga diamondi pazigawo zomwe zimafunikira kusamva kuvala.

Njira yopangira extrusion nthawi zambiri imakhala yoyenera kupanga zinthu za thermoplastic, zomwe ndizosiyana kwambiri ndi jekeseni wa jekeseni ndi mphira woponderezedwa.

6. Zithupsa nkhungu

Chikombole chomwe chimagwiritsa ntchito mbale zapulasitiki ndi mapepala ngati zipangizo kuti apange zinthu zapulasitiki zosavuta. Pankhani ya kufewetsa, imakhala yopunduka ndikumangiriridwa pabowo la nkhungu kuti ipeze chinthu chomwe chimapangidwa, chomwe chimagwiritsidwa ntchito kwambiri popanga zinthu zofunika tsiku ndi tsiku, zakudya ndi zonyamula zoseweretsa.

Nthawi yotumiza: Feb-12-2022